Aditya Birla Group has been producing yarn since India completed ten days of its independence. Here's a quick look at how the company plays a vital role in fulfilling one of the three fundamental needs of humanity

Aditya Birla Yarn is one of the leading producers of industrial yarns, and the largest textile player in India. But what exactly is yarn and why do we need it? Let's take a closer look at the product that has been clothing and protecting humankind for over 40,000 years.

Understanding Yarn

Yarn is a meticulously crafted assemblage of fibres or filaments, either natural or synthetic, that are interlaced to form textiles. Through the intricate process of spinning, fibres are meticulously lined up and twisted together, fortifying the resulting yarn with remarkable strength. That's what makes it an essential part of your t-shirts and curtains and even your car's safety belts and airbags.

Journey Through Time

Clothing being one of the three basic needs of man, the demand for yarn has only consistently grown with time. From the rich tapestries of medieval Europe to the intricate silk fabrics of China, yarn evolved beyond its basic purpose, into a medium through which stories, symbols, and identities were woven.

Ancient Origins

When it comes to the birth of yarn, pinpointing a singular time or place has been a challenge even for archaeologists. Some attribute the birth of yarn to India, while others believe Egypt to be its rightful place of origin. The oldest recovered artifacts made with yarn were string skirts dating up to 20,000 years ago. Meanwhile, fragmentary evidence of cotton fabric dating back to 3500 BC in Mexico further adds to the mystery.

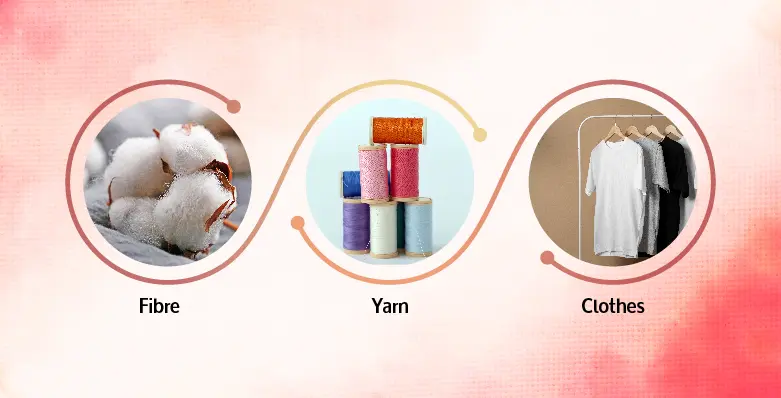

Fibre, Yarn and Apparel Difference

Fibre, yarn, and apparel are interconnected elements forming the hierarchical structure of the textile industry. Fibre represents the initial stage, where long continuous threads or filaments are extracted from trees, animals, and through other geological processes. These fibres are then spun into yarn, which is used to create fabric, and eventually apparel.

The Birth of Spinning

Spinning, the art of transforming fibres into yarn, is a simple yet intricate process that predates recorded history. Archaeological findings, including a representation of a Palaeolithic era skirt, suggest that spinning was initially performed by hand long before the advent of spinning wheels and spindles. Evidence of spindle whorls dates back to the Neolithic era, while the introduction of spinning wheels is believed to have occurred between 500-1000 AD in India.

From Natural to Synthetic

The quest for artificial fibres began in 1664 and was achieved in 1855 by the Swiss chemist Audemars. Rayon, a replica of silk, was born in 1889 thanks to French chemist Hilaire de Chardonnet, the 'father of the rayon industry'. Today, manufactured fibres offer unmatched diversity compared to natural ones. Aditya Birla Yarn alone produces 16 different brands of both natural and artificial fibres that fuel the world's textile industry.

Global Textile Vision

Aditya Birla Group's yarn business in Thailand, established by Mr. Aditya Vikram Birla in 1969, marked the company's first overseas expansion and the pioneering steps of an Indian company abroad. It followed Mr. Ghanshyam Das Birla's legacy, who established a rayon-based weaving unit just ten days after India's independence in 1947 to address the nation's fibre needs.

Weaving India's Textile Story

From fashion and home textiles to protective clothing and medical applications, Aditya Birla Yarn fulfils India's need for textiles across the spectrum. It is the number one producer of viscose staple fibre, viscose filament yarn and linen and worsted yarn in the country.

Spinning The Future

By 2030, the world will consume an approximate 140 million tonnes of yarn. With a presence in more than 70 countries and commanding a 13% market share globally, Aditya Birla Yarn has a strong foothold in both major and niche fibres, and is well on its way to meet the global demand for yarn.

Embracing Sustainability

Over half of Aditya Birla Yarn's 16 brands are sustainable, exemplifying the company's dedication to a greener future. They prioritize renewable raw materials like cellulosic fibres and use 90% recycled materials for packaging. Additionally, rainwater harvesting is integrated into their plants, and over 90% of their energy needs are met through renewable sources.