Hindalco's Birla Copper meets over half of India's annual requirement for copper. Here's a quick look at why copper, the metal that is both ancient and modern, is vital to the way we all live and work in the digital age

Found in everything from overhead wires and automobiles to the human liver, copper is elemental to human progress and wellbeing. It's also one of the oldest known metals. Here's a primer about copper's role in our lives and how India's number one copper producer, Hindalco, is meeting the nation's demand for this valuable metal.

Advantage Copper

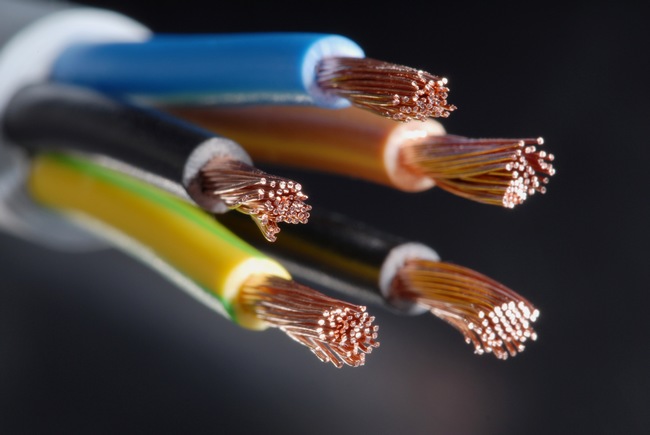

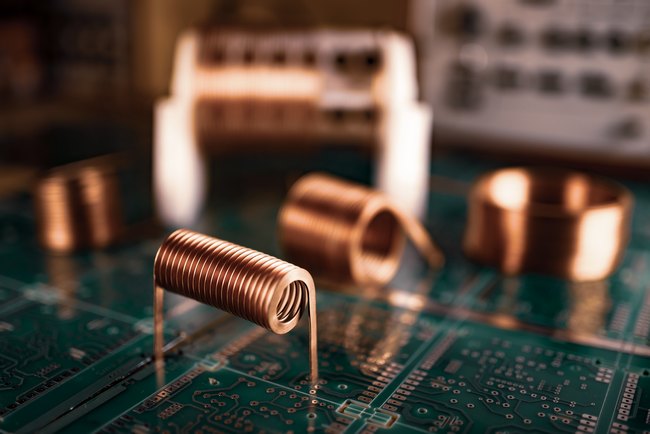

Copper's utility ranges from its long list of benefits. It is a superb conductor of heat and electricity; it is soft and malleable, making it easy to shape without breaking; and it is ductile, i.e., it can be readily bent or stretched into wires. It also has natural antibacterial and corrosion-resistant properties. Finally, copper is environment-friendly because it is 100% recyclable and doesn't degrade easily.

Ancient origin

There is evidence that humans smelted copper during the Neolithic Age. Testament to this is Ötzi, a 5,000-year-old mummified man whose frozen body was found on the Austria-Italy border in 1991. Along with the body, scientists retrieved an axe made from 99.7% pure copper. That, and the arsenic deposits found in Ötzi's hair, make it likely that he was involved in copper smelting.

Cypriot connection

The name copper comes from the Latin cuprum, translating to "from the isle of Cyprus". The Mediterranean nation of Cyprus was well known for its copper mines that supplied the precious metal to the island's Roman conquerors. Today, much of the world's copper is mined in countries like Chile, Peru, China and USA.

Material of choice

There is also evidence that copper plates (tamra-patras and tamra-shasanas) were used as early as the 3rd century BCE in India to record land grants and other legal information. Copper was probably the material of choice because it doesn't easily rust or decay. The earliest example of this is the Sohgaura copper plate inscription, which describes famine relief efforts during the Mauryan period.

Vital to health

The average human body contains between 50 and 120 milligrams (mg) of copper, most of which is stored in the muscles and liver. Copper is essential for forming blood cells, absorbing iron, and making energy. It also keeps the nerve cells and immune system healthy and is required to form the collagen found in our bones and connective tissue.

Demand for red

Hindalco serves more than half the country's demand for the reddish-brown metal. Birla Copper products find use in both home electrification as well as core sectors such as railways, power, construction, and automobiles. Copper is also used as a conductor in all digital devices, from smartphones to computers.

On track

Hindalco supplies multiple copper components to the Indian Railways. It is one of the country's major manufacturers of 19.6mm diameter copper rods, used in railway electrification. Its copper is also used in rail signalling systems, switchgear, brake systems, motor windings, and more.

Copper topper

On the industrial front, copper is essential for digitisation and electrification. Thus, the demand for copper is an indicator of the growth of an economy. Incidentally, India's consumption of copper is expected to more than double over the next decade.

Expanding capacity

To meet India's massive demand for the red metal, Hindalco's Birla Copper runs a world-class plant at Dahej, Gujarat, which is one of the largest single-location custom copper smelters in Asia. Today, Hindalco has the world's third-largest copper rod capacity outside of China. Over the past five years, the company has expanded its downstream copper rod manufacturing capacity by four times.

Inorganic expansions

Hindalco is also growing through acquisitions. In 2021, it fortified its downstream portfolio of copper rods by acquiring Ryker Base Private Limited, now known as Birla Copper's Asoj Unit. The acquisition added 225,000 tons to Hindalco's existing capacity of 345,000 tons, and will help it cater to growing demand from the electrical and electronics sectors.

Value from waste

One of the principles of circularity in manufacturing is that one unit's waste can become another's raw material. Aditya Birla Group uses copper slag – the by-product of copper smelting – as a substitute for river sand while making ready-mix concrete (RMC). Through rigorous trials, the Group's scientists found that copper slag can replace up to 50% of the sand used in RMC.

Powering the future

Copper is powering a more sustainable future for all of us. The metal plays a critical role in next-generation technologies like electric vehicles, smart cities and green buildings, solar panels, and storage batteries, among others. And Aditya Birla Group is leading the way in meeting the copper demand from these sectors.